Embossing in the electronics Industry often refers to producing graphic displays with raised elements. We offer a wide variety of different graphic displays with several different types of embossing. Which type of embossing is right for your application depends on how exactly the device will be used and on your own personal preferences. You can call us and speak to one of our engineering professionals, and we will listen to the specifications that you provide and give you a suggestion about which type of embossing is right for your graphic overlay. The types of embossing include pad, perimeter, and dome embossing. To learn more about embossing in this context, read on.

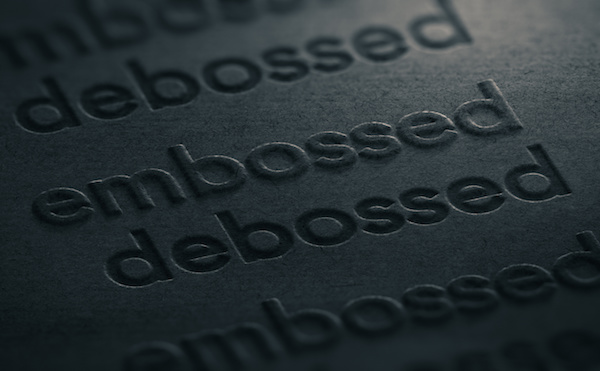

Embossing and Graphic Overlays

Embossing is often used in graphic overlays to make them more ergonomic and increase usability. They are especially popular for graphic overlays that will be used in low-light situations, as users will be able to pick out keys simply by touch. This would not be possible if the keys were flat against the display. Even for graphic overlays that are not in low-light applications, embossing is quite popular because it provides a more tactile feel and reduces missed attempts to press keys. Embossing is good for low-light situations and situations where keys must be pressed quickly.

Pad Embossing

One of the types of embossing we offer is called pad embossing. Pad embossing raises the entire key area above the surface of the overlay. This is generally used for keypads that have only a few keys. If there are many keys, pad embossing may actually make the device uncomfortable for use because the raised area is too large. It is, however, good for when the overlay is over a display that you do not want to get fingerprints or skin oils on. Raising the entire key area will reduce the risk of this happening. This will help ensure a longer life for the device and less required maintenance.

Perimeter Embossing

Perimeter embossing is possibly the most popular type of embossing. This process is also called rim embossing. It involves raising a ridge around the edge of the key. This gives the keys a more tactile feel and allows greater accuracy when using the device. It also helps users find the keys in low-light situations.

Dome Embossing

Dome embossing is a specialty type of embossing that is often used for ATMs, vending machines, and other machines that have an extremely high rate of usage. The sort of embossing raises a tactile dome around the whole key area. This helps the user find the key they looking for and press it more quickly. It may only shave a second or two off of each interaction, but if the keypad sees thousands of interactions per day this is a meaningful time saving. Dome embossing can also make the keys easier to read

Which Type of Embossing is Right for Your Application?

If you’ve decided that your graphic overlay needs to be embossed, you must choose between one of the three types of embossing. They all have their unique characteristics and make them right for certain applications, but which one is right for your application? Dome embossing is probably the best option if the graphic overlay will be going on a machine that sees a very high number of users. Pad embossing is probably the best option if the graphic overlay is over a display which fingerprints could mark or damage. Rim embossing maybe the right option if the keypad is going to be in a low-light area. If you speak to one of our engineering representatives and tell us about the application you will be placing the keypad in, we can recommend a type of embossing.

Embossing Or No Embossing?

Now you know quite a lot more about embossing and which type of embossing you should choose for your application. However, it possibly may not be right for your application at all. It can be useful for any graphic overlay, but it is not necessary for some situations. Embossing does costs more and it does take a little more time. If your graphic overlay will be in a fairly low traffic and well-lit area, it may not need embossing.