If you have an electronic device, it probably has a printed circuit board (PCB). These boards are responsible for the operation of electronic devices. But what are these key aspects of electronics, how are they made, and how did they come to be so important?

What is a Printed Circuit Board?

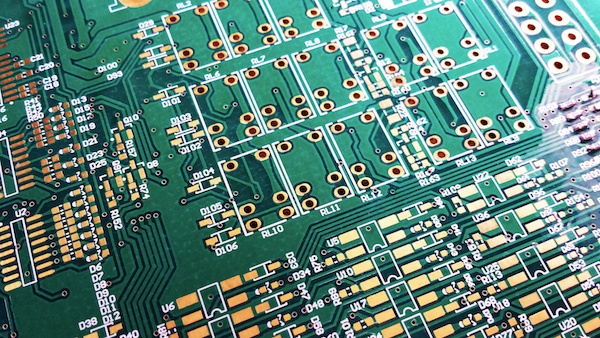

Printed Circuit Boards are boards that connect various points together through lines and pads. They allow signals and power to connect between two separate physical devices. While the term “printed circuit board” is typically used, other terms to describe these include “printed wiring board” and “printed wiring card.”

Before PCBs came into existence, circuits were constructed using point-to-point wiring. This led to the failure of wire junctions and short circuits if the insulation would age or crack. It was because of this that the need arose for a more durable unit. The answer would be PCBs.

PCBs also became a need as electronics became more common in consumer goods. To ensure that these every day electronics had all of the necessary components, the size and manufacturing costs needed to be reduced. Thus came the invention of PCBs.

History of the Printed Circuit Board

Printed circuit boards were first used in the 1940s as a way to connect discrete components such as resisters and transistors. By the 1960s, while electronic systems were still mostly using these discrete components, PCBs were beginning to be widely used. As time progressed, integrated circuits, known as chips, began to emerge and were subsequently added to circuit boards. When the 1980s arrived, PCBs contained a large number of chips. As technology has progressed, PCBs have moved further away from discrete components and closer to chips which contain a few thousands to hundreds of millions of transistors. Today’s PCBs connect mostly chips with very few discrete components.

What are Printed Circuit Boards Made of?

The substrate, or base material, of a PCB is typically fiberglass. The fiberglass that has historically been used for this purpose is designated as FR-4, a flame resistant, woven fiberglass. The next layer is a thin copper foil which is laminated to the board using heat and an adhesive. On top of the copper foil is a soldermask layer. The purpose of the soldermask layer is to insulate the copper to ensure no other metals come into contact with it. The final layer is silkscreen. This is the layer that will add the letters, numbers, and symbols that are commonly seen on PCBs.

What are Etched Circuits?

Printed circuits are really etched circuits. These circuits can have very few layers or several layers. A copper foil is placed over the fiberglass or a plastic base of each of the layers and is covered with photoresist, a material that loses its resistance or susceptibility to an attack by an etchant or a solvent when exposed to light. When light is sent through the negative image of the circuit paths and onto the photoresist, the areas that remains following the etching are hardened. Any unhardened areas are washed away by an acid bath. To complete the process, the finished layers are glued together.

Why Hallmark Nameplate?

Hallmark Nameplate is a company that features experienced professionals when it comes to assembling PCBs. Their services include PCB assembly, testing, PCB encapsulation, prototype PCB assembly, and PCB engineering. As an ITAR-certified producer of PCBs, Hallmark Nameplate hold themselves to a high standard producing military-grade products. This ensures that anything PCB assembled by Hallmark Nameplate will be of the highest quality.

The functionality and construction of electronics has developed dramatically over the years. As technology has advanced, the need for printed circuit boards has increased. Even after PCBs were invented, most electronics featured more discrete components than chips. However, as manufacturers attempt to make smaller and less expensive devices, chips are more common than discrete components making PCBs that much more important.

When having PCBs manufactured or assembled, it is imperative that it is done to the highest quality to ensure maximum functionality of electronic devices. Hallmark Nameplate is an ITAR-certified company and a member of the Special Graphic Imaging Association (SGIA). They are leaders in the industry and are held to the highest standards. So if you’re in need of PCB assembly services, look no further than Hallmark Nameplate.