When it comes to product manufacturing, knowing the difference between ODM vs OEM is an important distinction. The key takeaway is that ODMs (Original Design Manufacturers) create products based on their designs sold under a client’s brand. In contrast, OEMs (Original Equipment Manufacturers) make products according to the specifications and designs provided by the client.

While both involve outsourcing, they differ in terms of design control, customization, and branding. In this blog, we’ll explore the key differences between ODM vs OEM and help you determine which model best fits your manufacturing needs.

Let’s dive right in!

Original Design Manufacturing

As mentioned above, an ODM creates products based on their own designs, which other companies then rebrand and sell under their own name. This is a common approach in industries like electronics, fashion, and home appliances, where businesses want to offer unique products without investing in the design process themselves.

For example, Asus is a Taiwanese ODM in the electronics manufacturing business. Asus designs and manufactures laptops that are rebranded and sold by other companies, such as Dell or Lenovo. These companies rely on Asus’s design expertise and manufacturing capabilities to produce high-quality laptops without needing to create the designs themselves.

Moreover, this allows them to quickly bring products to market with the assurance of a proven design. Sounds like a sweet deal, right? Well, there are pros and cons to working with ODMs. Let’s outline those below.

ODM Advantages

- Time and Cost Savings: Since the product design is already complete, companies can save time and money by skipping the design phase and going straight to production.

- Speed to Market: With a ready-made design, products can be produced and brought to market more quickly.

- Less Effort: Companies don’t need to worry about the complexities of product design, allowing them to focus on marketing and sales.

As you can see, the benefits of partnering with ODMs can be great for your company. Time and cost savings are usually the top advantages, but there are also some drawbacks. Keep reading to learn more.

ODM Challenges

- Less Control: Since the design is owned by the ODM, there’s less flexibility to make changes or customizations.

- Limited Uniqueness: Because the design isn’t exclusive, other companies may offer similar products, making it harder to stand out in the market.

While the pros of ODMs outweigh the cons for some companies, others want to have more control over the design of their products. This is where OEMs come in.

Original Equipment Manufacturing

Unlike ODMs, OEMs don’t create their own designs but instead bring a client’s unique concept to life. This approach is common in industries like automotive, electronics, and medical devices. Oftentimes, these companies have detailed and proprietary designs that need to be manufactured to exact standards.

For example, Bosch is an OEM in the automotive industry that is based in Germany. Bosch manufactures specific parts like brakes, sensors, and fuel injectors based on the exact designs provided by car manufacturers like BMW or Ford.

These car companies design the parts to meet their unique requirements and brand standards, and Bosch produces them to those precise specifications. Then, the final components are then integrated into the vehicles. This allows the car manufacturers to maintain complete control over the design and quality of their products.

OEM Advantages:

- Full Control: Companies maintain complete control over the design and specifications, ensuring that the final product meets their exact requirements.

- Customization: OEMs can tailor the product to the client’s precise needs, making it easier to create unique products that stand out in the market.

- Brand Integrity: Since the design originates from the client, the final product aligns perfectly with the brand’s vision and values.

This level of customization and control allows companies to create truly unique products that can differentiate them in the market.

OEM Challenges:

- Higher Costs: Developing a custom design can be more expensive and time-consuming compared to using a pre-designed product from an ODM.

- Longer Development Time: The process of creating a product from scratch typically takes longer, as it involves extensive design, prototyping, and testing.

- Increased Complexity: Managing the design and production process requires more coordination and expertise, which can be challenging for companies without extensive experience in manufacturing.

In summary, outsourcing an OEM requires a greater investment of time, resources, and expertise to ensure that the final product meets the desired standards. It’s always better to find a manufacturer that is credited and has a years of expertise, like Hallmark Nameplate.

Comparing ODM vs OEM

When deciding between an ODM and an OEM approach, it’s essential to consider several key factors that impact your product’s development and overall business strategy. Now that you understand the different types of manufacturing, let’s compare the two.

Design Ownership

In an ODM model, the manufacturer owns the design, which means your product is based on a pre-existing blueprint. This can be a quick and cost-effective solution but offers limited flexibility if you want to make changes.

On the other hand, with an OEM, you retain full ownership of the design. This allows you to create a product that is entirely unique and tailored to your specific needs, but it also requires more time and investment to develop.

Customization Options

Generally, ODM products offer limited customization. You may be able to modify certain aspects like color or branding, but the core design remains the same across all products made by that ODM.

Conversely, OEM products are highly customizable since they are built according to your exact specifications. This allows for greater differentiation in the market that can help you stand out from competitors.

Cost Considerations

Cost is a significant factor when choosing between ODM and OEM. ODMs typically offer a more affordable solution since the design and development phases are already completed, and you’re essentially buying into a ready-made product. This makes it an attractive option for companies looking to reduce upfront costs.

On the flip side, OEMs usually come with higher initial costs due to the need for custom design and development. However, this investment can pay off in the long run by delivering a unique product that potentially commands higher market value.

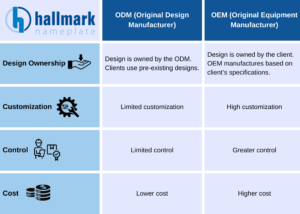

ODM vs OEM Comparison Table

To further aid in your understanding of ODMs vs OEMs, take a look at the following table.

Find the Perfect Fit: Manufacturing Solutions Tailored for Your Business

Choosing between ODM vs OEM depends on your specific needs, whether you prioritize cost-efficiency and quick market entry or customization and control over the design process. At Hallmark Nameplate, we understand that selecting the right manufacturing approach is crucial for your business’s success.

Whether you’re looking for detailed customization or cost-effective solutions, our team is here to assist you in making the best choice for your needs. Visit our website today to get a FREE quote and explore how we can support your manufacturing goals.