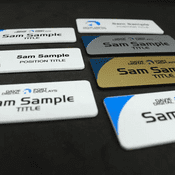

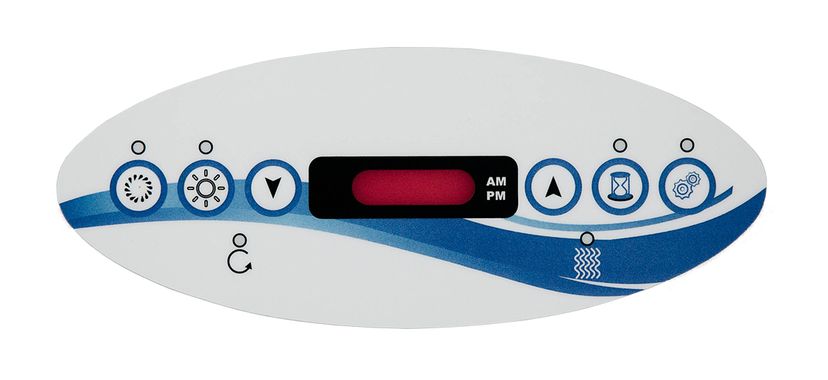

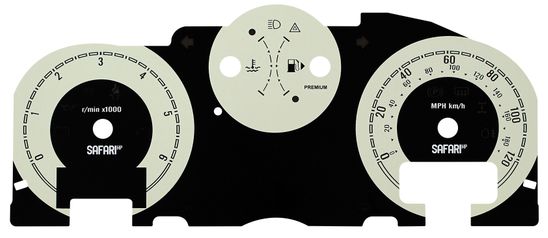

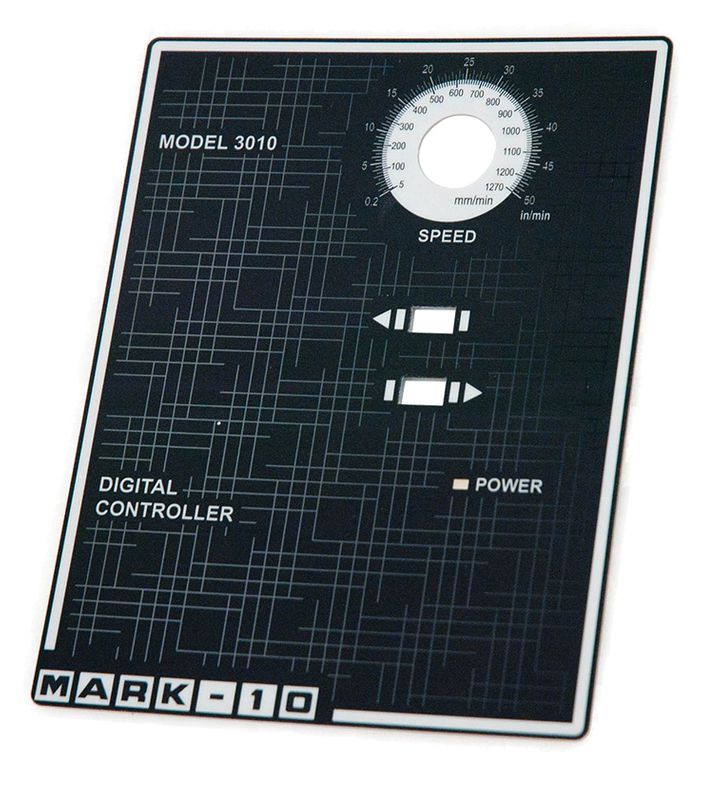

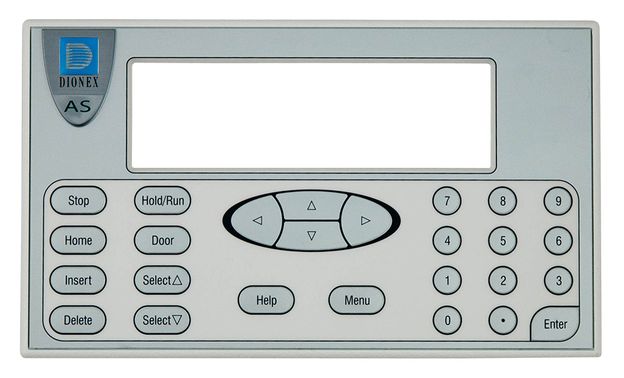

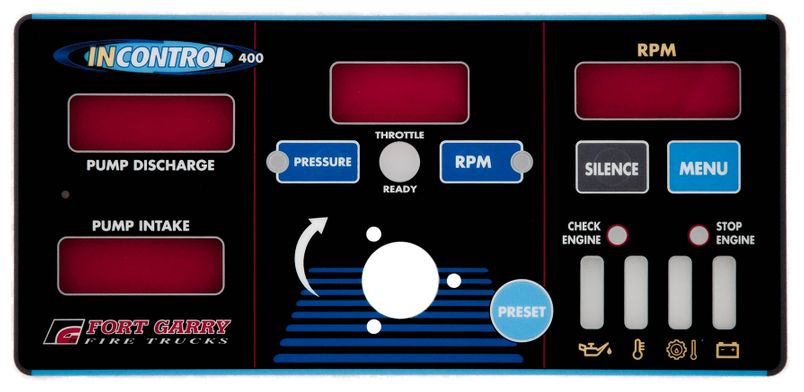

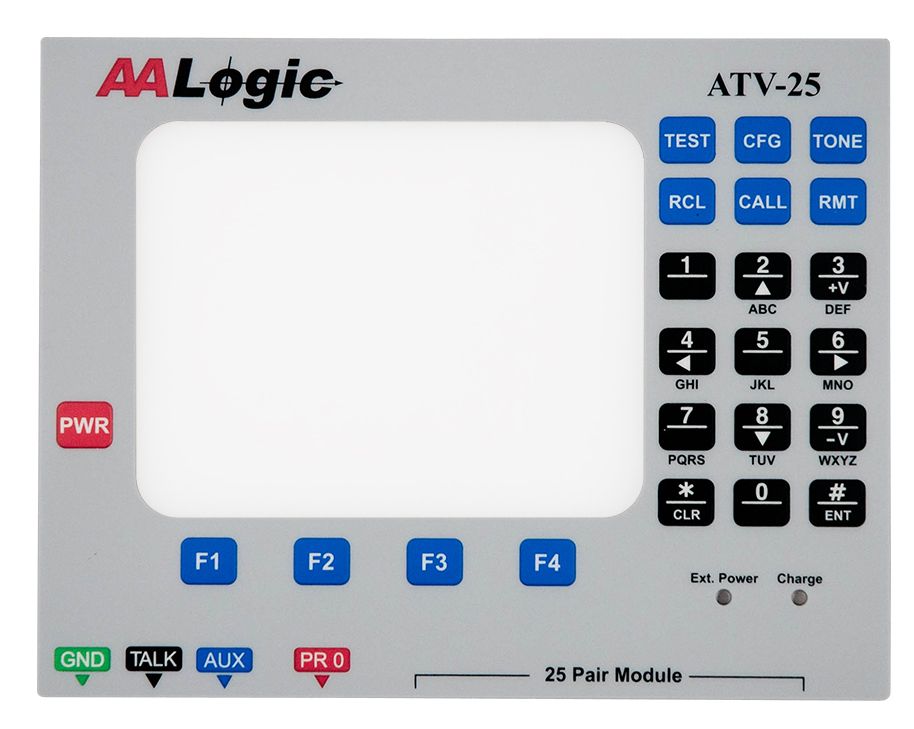

Custom Nameplate Examples

Client Testimonials

General Manager

Mining Equipment Manufacturer

“We are very pleased with the prototypes. Pinouts are good to go. Dimensions were on point. Please proceed and thank you for the quality work!”

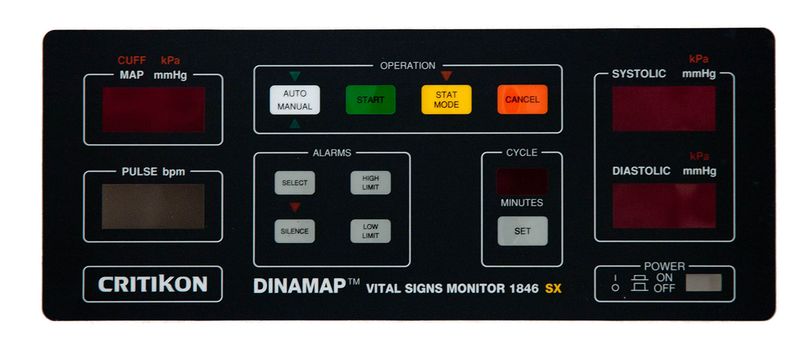

CEO

Data Monitoring Device Manufacturer

“I really appreciate the quick turnaround on questions, quotes etc. Greatly appreciated!”

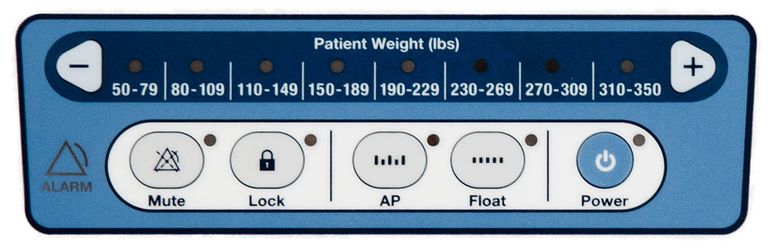

Buyer/Planner

Medical Device Manufacturer

“Hallmark has impressed the Robotics Solutions team with the work you recently completed for us. Looking forward to your quotation. Thank you to all and stay healthy and safe!”

FAQ

Our Certifications

Ask Our Experts About Equipment Solutions

Our experts are always ready to help. Get in touch with us and we'll find the right solution to meet your needs.