Any industry using printed circuit board (PCB) based membrane switches needs a connector to work. Although the function is universal, the choice of connector options for PCB based membrane switches has challenges with meeting visual and operative requirements. One reason is the continuing reduction of electronic device sizes as technology advances. Our engineering designers are blending both the ability and work solutions for a variety of applications. We focus on educating our clients about the emerging trends on how to connect the electronic membrane switches to the product’s keyboard and control schematics.

Connectors fit the contact device using wires, pins and molded housings—it is not always a simple task to select the right connector for PCB based membrane switches. Connectors need to complement the application adding equipment durability within the limited space. Our switches include both tactile and non-tactile switches. PCB actuator switches support keyboard and touch screens. The goal is to make sure the transitory switching happens without failure.

Today, our membrane switch technology is dependable and designed to meet the changing market demands. Membrane switch designs have adapted to developments demanding components that are more durable and easily integrated using connectors. Choosing the right connector to perform the job is our specialty.

Trends for PCB Membrane Switches

PCB based membrane allows for a better choice of connectors. The benefits of connectors are the ability to disconnect when replacing the power input, peripheral connections or PCBs. New connectors make it easier to integrate into other systems and devices. Advances in PCB applications make it more compatible with a membrane switch that has a low profile, flat surface keypad assembly. Design updates improve the reliability, increases operating life with lower switch resistance.

If you are looking for application-specific solutions that meet product and industry standards call us. Our design team can create a connector solution that fits your control systems and product standards. Our commitment to you is rapid response keeping you active in today’s market.

As a product manufacturer, our goal is to help you keep the highest level of performance as a preferred supplier to your industry. We will configure the right solutions creating efficiency between your operational functions and industry demands.

PCB Connector Options

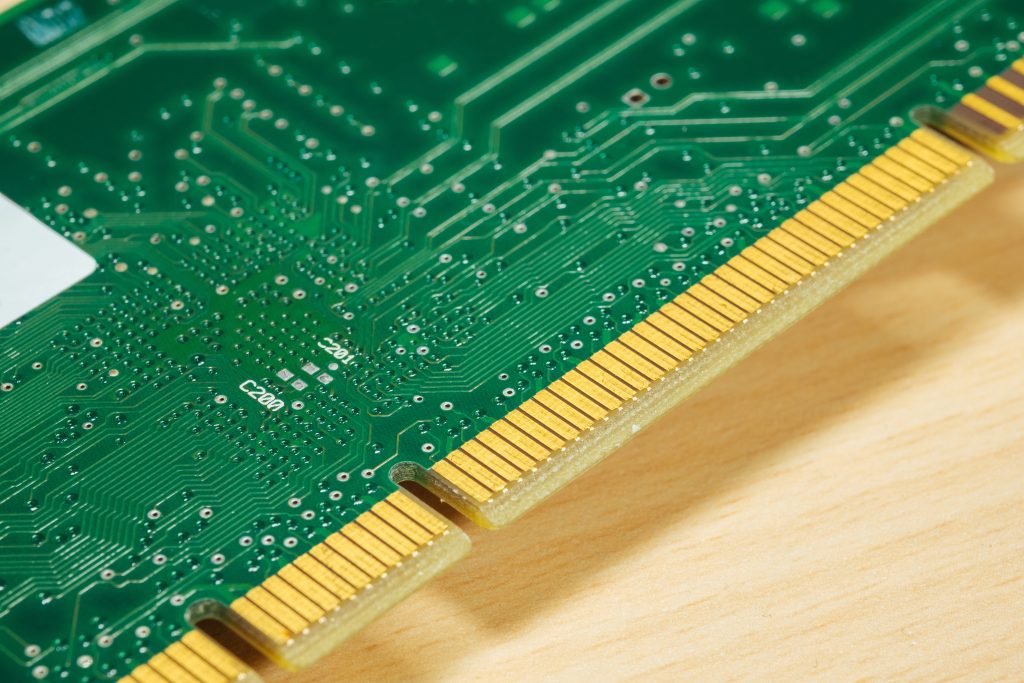

Technology has changed how we connect in the world of electronics. Today, flexible membrane switches connect using a flexible tail cut from the PCB material. The design allows the tail to connect to a PCB with single or multiple row connectors, designed for your equipment. You have multiple options for choosing connectors from pricing to feature functions. Our staff can help replace outdated or worn components saving time and money.

For connectors, the most economical choice of connector designed has an easy insertion. It has an interconnect capacity with a terminating feature using solder tabs that can be soldered to the PCB. This connector does not connect directly to the membrane switch—it connects to the PCB. The tail circuit inserts into the receptacle connector to make contact. Technology attaches the wire to the PCB inside of electronic devices. The ribbon cables contain the wires with bare ends placed inside of a connector. It is a single connector solution.

Traditional male, female or solder tab housings connectors need a mating half to fit the opposite wire ends. These have proven to work well in industrial environments with heavy shock or vibration. The connectors have pins crimped to the circuit, assembled into a housing design for protection and handling. These pre-terminated connector designs enable rapid installation and deployment. We can change the tail options to fit existing equipment connections or quality upgrades to the latest industry standard.

Conclusion

We integrate function controls into smaller spaces for you without the loss of quality or usability. Our systems improve equipment, component, and user operational interfaces. Even with the advancements of smaller PCBs and other components, we offer state-of-the-art devices with enhanced capabilities. Existing industry PCB based solutions can be costly or they lack the operational efficiency needed. As one of the most experienced membrane switch designers, we can configure PCB based connectors with precision. We do it by offering integrated components and assembly using our unique process ensuring compatibility.