In order for production lines to run smoothly, effective labeling is key. The correct manufacturing labels allow products to be easily traced and identified throughout the manufacturing process. Not only are they integral throughout every stage of the manufacturing and delivery processes, but they also streamline production.

In this blog, we’ll explore seven key practices in which manufacturing labels can optimize your production line, from reducing errors to accelerating workflow. By implementing these strategies, you can achieve greater productivity and maintain a competitive edge in the industry.

Without further ado, let’s dive right in!

What Are Manufacturing Labels?

Manufacturing labels are used within manufacturing processes to provide critical information, enhance organization, and ensure product traceability and compliance. These labels can contain various types of data, including:

- Product Identification: Details about the product such as part numbers, serial numbers, batch numbers, and barcodes for easy tracking.

- Process Instructions: Specific instructions for handling, assembly, or processing, helping workers perform their tasks accurately.

- Quality Control: Indicators for quality status, such as inspection results, pass/fail marks, or testing dates.

- Compliance Information: Regulatory and safety information, ensuring that products meet industry standards and legal requirements.

- Logistics Information: Data for shipping, receiving, and inventory management, including destination addresses, storage instructions, and inventory codes.

These labels are typically made from durable materials to withstand various environmental conditions such as heat, moisture, chemicals, and abrasion. By providing clear and accessible information, manufacturing labels help improve efficiency, reduce errors, and maintain quality throughout the production process.

How Industries Apply Manufacturing Labels

Since manufacturing labels are such an integral part of production, many industries use labels to streamline their processes. Let’s discuss some ways that these industries apply manufacturing labels to their operations.

Automotive Industry

In the automotive industry, manufacturing labels are used extensively to manage complex supply chains and assembly processes. Labels on parts and components include barcodes, serial numbers, and QR codes to support precise tracking from the supplier to the assembly line.

For instance, an engine component might have a label with a QR code that links to detailed manufacturing data and quality control records. This ensures traceability and accountability throughout the process.

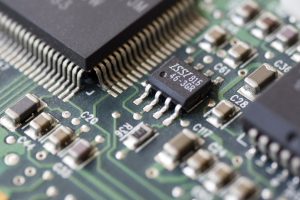

Electronics Manufacturing

Labels provide essential product details and regulatory information in electronics manufacturing. For example, a circuit board might have labels indicating its part number, production date, and compliance with international standards like RoHS (Restriction of Hazardous Substances).

This ensures that each component meets the necessary safety and environmental regulations and can be easily tracked.

Food & Beverage Industry

In the food and beverage industry, labels are critical for conveying safety information, expiration dates, and batch numbers. For instance, a packaged food item will have labels indicating its ingredients, nutritional information, and allergy warnings.

Batch numbers on these labels enable manufacturers to trace products back to their production runs. This helps facilitate efficient recalls if necessary and ensures consumer safety.

Medical Devices

Manufacturing labels in the medical device industry carry vital information to comply with strict regulatory standards. A medical device, such as a blood glucose monitor, will have labels displaying its unique device identifier (UDI), lot number, and expiration date.

Not only is this information crucial for managing inventory and tracking the device through its lifecycle, but it also ensures that only safe, effective products reach the market.

Aerospace

Aerospace manufacturers use labels to manage the stringent documentation and tracking requirements for aircraft components. Labels on parts such as turbine blades and avionics systems include serial numbers, part numbers, and certification marks.

These labels ensure that each component can be traced back to its origin, confirming that it meets all necessary quality and safety standards before being installed in an aircraft.

7 Key Ways to Streamline Production With Manufacturing Labels

Now that you understand the basics of manufacturing labels, it’s time to discuss the key ways these labels streamline production. So, here are seven best practices to keep in mind when integrating manufacturing labels into your processes.

1.) Enhance Traceability

First, manufacturing labels enable precise tracking of components and products throughout the production process. By incorporating barcodes, QR codes, and serial numbers, you can monitor the movement of items from raw materials to finished goods. Consequently, this traceability improves inventory accuracy, facilitates rapid issue resolution, and supports efficient recall management if necessary.

2.) Improve Inventory Management

Furthermore, labels help maintain accurate inventory levels by providing clear identification of parts and materials. With detailed labels, you can quickly determine stock levels, track usage rates, and reorder supplies before they run out. This minimizes downtime and ensures that production lines are always adequately stocked.

3.) Streamline Quality Control

In addition, quality control is a vital aspect of manufacturing, and labels play a significant role in this area. Labels can include inspection dates, test results, and quality assurance statuses. This guarantees that only products meeting quality standards proceed through the production line, thus reducing the risk of defects reaching customers.

4.) Facilitate Assembly Processes

Moreover, labels containing assembly instructions, diagrams, and part numbers simplify the assembly process. Workers can quickly identify components and follow step-by-step instructions, which ends up reducing errors and speeding up production. This is particularly useful in complex assemblies where precision and accuracy are critical.

5.) Ensure Regulatory Compliance

Compliance with industry regulations is essential for avoiding legal issues. Manufacturing labels help ensure that products meet all required standards by displaying regulatory information, such as compliance marks, safety warnings, and certification details. Not only does this minimize the risk of non-compliance penalties, but it also enhances the credibility of your products. It’s a win-win!

6.) Improve Workplace Safety

Additionally, safety labels provide crucial information to protect workers and ensure safe handling of materials. Labels with hazard symbols, handling instructions, and emergency procedures help prevent accidents and ensure that safety protocols are followed. By creating a safer work environment, manufacturing labels help reduce the risk of workplace injuries.

7.) Enhance Customer Satisfaction

Finally, manufacturing labels can include customer-specific information such as order numbers, customization details, and special instructions. This ensures that each product is tailored to meet the customer’s exact requirements which reduces errors and improves satisfaction.

Clear, informative labels also provide customers with essential product information that enhances their overall experience and trust in your brand.

As you can see, implementing effective labeling solutions helps streamline operations, reduce errors, and ensure that your manufacturing runs smoothly and effectively. So, how can you do this for your business? Well, that’s where Hallmark Nameplate comes in.

Elevate Your Production Efficiency With Hallmark Nameplate

Manufacturing labels provide more than just a simple product marker. They improve efficiency, quality control, regulatory compliance, and customer satisfaction. Whether you require robust traceability systems, compliant labeling for regulated industries, or customized solutions to enhance customer interaction, our expertise ensures that your labeling needs are met with excellence.

At Hallmark Nameplate, we understand the critical role of precision and reliability in labeling solutions. So when it’s time to find your label manufacturer, trust that we will exceed your expectations.

Partner with us to elevate your production efficiency and deliver exceptional quality every time. Visit our website to learn more and request a FREE quote!