As a business owner or manager, you are always looking for ways to improve your business and make more money.

But instead of trying to cut corners in production, you should work to maximize your business’s productivity. But how?

Improving your overall equipment effectiveness is a great place to start.

But what does that mean, and how do you get started on making changes?

In this article, we will discuss:

- How to calculate your overall equipment effectiveness so you can see where you started and track your progress.

- 7 ways you can enhance your productivity and in turn improve your OEE.

- Where you can manufacture high-quality equipment to improve your OEE.

Let’s dive in!

How To Calculate Overall Equipment Effectiveness

First lets, discuss what overall equipment effectiveness (OEE) means. It is the percentage of planned production time that actually ends up being productive.

100% = perfect production

85% = top of class

60% = average

40% = starting off

As you can probably guess, your ultimate goal is 100%, but 85% is a more practical, long-term goal for most companies.

OEE Formulas

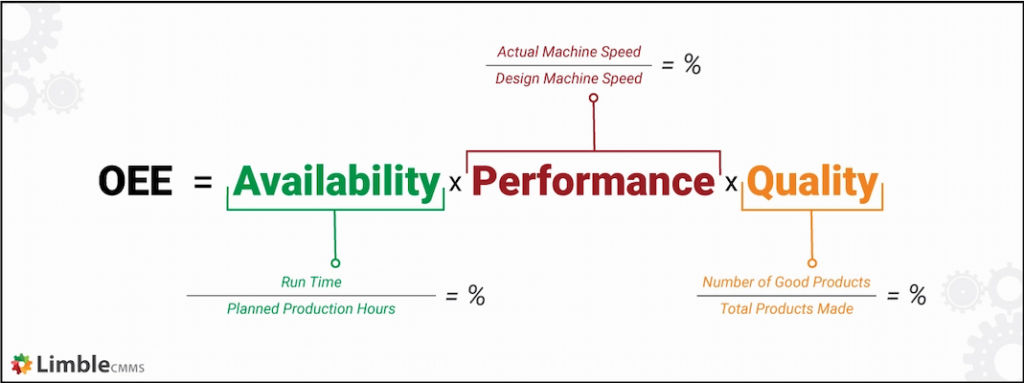

There are two different ways you can go about calculating your overall equipment effectiveness. The latter is preferred because it provides more information on the underlying factors for loss in productivity.

OEE = (Good Count × Ideal Cycle Time) / Planned Production Time

Or

OEE = Availability * Performance * Quality

Availability = Run Time / Planned Production Time

Run Time = Planned Production Time − Stop Time

Performance = (Ideal Cycle Time × Total Count) / Run Time

Quality = Good Count / Total Count

OEE Definitions

Here are a few definitions to help understand the formulas.

Good count: parts manufactured without defects

Ideal cycle time: the estimated fastest possible time to manufacture one part

Planned production time: time the production part is scheduled for production

If your OEE is at 60% or below, then you need to get serious about improving your productivity.

7 Ways You Can Improve Your Business’s Productivity & OEE

When you take longer on projects than expected, it can affect your finances. From having to pay more for facility rent and your employee’s time to taking on fewer clients, your costs are likely to increase while your profits will only decline.

Here are 7 ways you can improve your productivity and overall equipment effectiveness and in return earn more profits.

1. Improve Staff Efficiency

Is your staff producing at lower levels than you’d like? It may be because of the equipment they are using.

When their controls and switches aren’t easy to use, it can cause speed loss and delays in their production. By designing your equipment internally with a manufacturing partner, you can take into account what your employees need.

Take a look at how they interact with the controls currently, what they use often, or what is obsolete. From there you can design a user interface that is seamless for your employees to use.

2. Minimize Errors & Safety Issues

When your employees don’t know how to use their equipment, it can lead to injuries and malfunctions.

With graphic overlays and labels, you can ensure there are clearly marked instructions on the equipment. When there are fewer mishaps on the production floor, everyone can work efficiently, and there is no need for downtime.

Additionally, clear instructions can save you time because now your employees know the most efficient way to use the equipment instead of playing guessing games.

3. Decrease Downtime

As any business owner knows, time is money. Therefore, downtime is just your business hemorrhaging money.

When your equipment has an electronic failure, sometimes you have to shut down production entirely to fix or replace the broken part. That’s why it is important to work with a manufacturing partner who tests all electrical components to ensure high-quality electronic assembly.

With tactile switches, you improve the durability of your equipment so you do not have to stop to replace switches as often. Additionally, you can use them as often as you’d like without worrying about burning them out.

4. Reduce Cleanup

There’s nothing worse than having to repeatedly stop your work to fix a machine or give your tools a heavy-duty clean. With graphic overlays, you can add an extra protective layer to your equipment to increase its lifespan and reduce the need for maintenance and cleanup.

Additionally, using membrane switches instead of mechanical switches can reduce cleanup, requiring only occasional dusting.

5. Increase Visibility

Industries that use heavy-duty equipment, such as agriculture need complete visibility to maintain safety. Therefore, during dark or extreme weather conditions, they need to stop working for the day or move slowly.

Backlight membrane switches allow workers to see controls in dark or stormy conditions so they can continue to work efficiently- rain or shine. You can choose between electroluminescent (EL) or light-emitting diode (LED), although LED lasts longer and is more energy efficient.

6. Eliminate Confusion

As we mentioned earlier, when your staff can’t work their equipment correctly, they won’t be efficient. If they are not able to easily locate their controls, it can lead to longer production times.

Membrane switches with embossed areas and tactile feedback allow the operator to quickly distinguish the control pad when the area is embossed or raised to the next level. For even greater touch recognition, perimeter or dome embossing of individual keys reduces operator selection errors.

7. Increase Response Rate

If your equipment utilizes touch screens like smartphones or tablets, then they may be suffering from delays and errors due to technical issues.

Tactile membrane switches allow the device they are integrated into to be more responsive. Therefore, your team can utilize their devices with fast response rates and improve their overall results.

Additionally, with increased responsiveness, the device is more capable of handling several tasks at once so your staff can get more done in a fraction of the time.

Improve Your Productivity With Hallmark Nameplate

Looking to improve your business’s productivity and overall equipment effectiveness? At Hallmark Nameplate, our expert team of designers and manufacturers will work with you to design the perfect equipment for your needs.

From durable and clear graphic overlays to high-quality membrane switches and electronic assemblies, we will make sure your team can efficiently use your equipment.

Want to learn more? Visit our website to request a quote or get in contact with our experienced staff members.