Hallmark Nameplate offers quality engineering design support, in-house testing and quality control, and ISO 9001:2008 registration as well as ITAR certification. You can rest assured that Hallmark Nameplate products are manufactured to the highest standards. This is due, in part, to our state of the art equipment

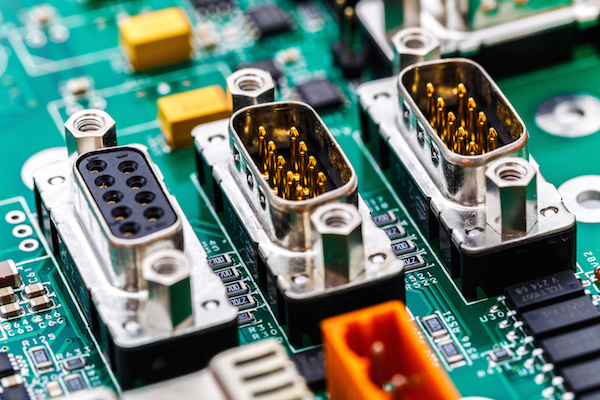

Our Electronic Manufacturing Services include:

- PCB Assembly

- Flexible Circuit Assemblies

- SMT/Through-Hole Technologies (Tin Lead and Lead Free)

- New Product Introduction

- Quick Turn Prototypes to Mid-volume Production

- Conformal Coating Services

- Box Build

- Testing/Programming Solutions

Some of our equipment includes:

- SMT state of the art Samsung Lines

- Electrovert OmniMax Ovens

- Electrovert Wave Solder Machine

- KISS selective solder machines (Tin Lead and Lead Free)

- YesTech Automated Optical Inspection Machine

- Nordson Dage X-ray Machine

- SPEA Compact 3030 In-circuit Tester

- PVA Conformal Coat Machine

- Through-hole Slideline Racks

- Pace Certified Hand Soldering Stations

- 45x Stereo Microscopes at all soldering stations

- High Precision Router

- Pace Hot Air Rework Station

For any electronic assembly issue you’re facing at the product manufacturing stage, Hallmark Nameplate is equipped to provide high-quality, reliable solutions!