Our Certifications

Client Testimonials

General Manager

Mining Equipment Manufacturer

“We are very pleased with the prototypes. Pinouts are good to go. Dimensions were on point. Please proceed and thank you for the quality work!”

CEO

Data Monitoring Device Manufacturer

“I really appreciate the quick turnaround on questions, quotes etc. Greatly appreciated!”

Buyer/Planner

Medical Device Manufacturer

“Hallmark has impressed the Robotics Solutions team with the work you recently completed for us. Looking forward to your quotation. Thank you to all and stay healthy and safe!”

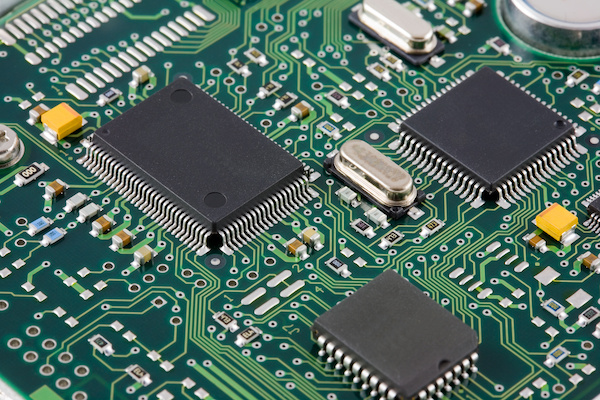

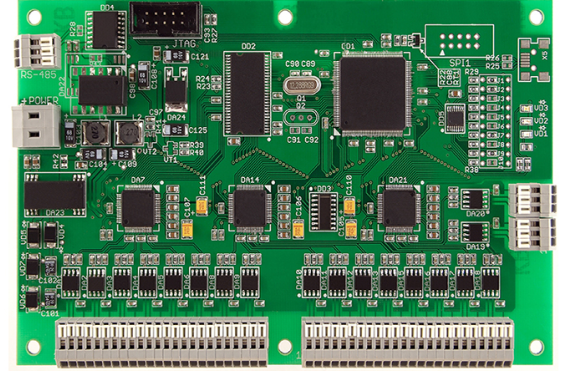

Unmatched Excellence in PCB Manufacturing

Are you searching for high-quality PCB manufacturing & assembly services? Whether it's crafting the initial prototype or scaling up to large-scale production, our PCB manufacturing & assembly capabilities ensure unmatched quality at every stage. With our dedication to quality and innovation, we stand out among PCB manufacturing companies.

As a trusted PCB supplier, we ensure meticulous design, precise component placement, intricate tracing of circuits, and rigorous testing to guarantee that your electronics perform flawlessly every time. If you're seeking a PCB prototype USA manufacturer or a custom PCB manufacturer, our comprehensive services are designed to exceed your expectations.

PCB Manufacturing & Assembly Services

Whether you’re developing a one-off prototype or scaling for mass production, our capabilities include:

Prototype Assembly

Fast, high-quality assembly to help you test and refine your design with a PCB prototype USA manufacturer.

Production Assembly

Scalable solutions for medium to high-volume manufacturing.

Box Build Assembly

Scalable solutions for medium to high-volume manufacturing.

Turnkey Assembly

We handle everything from sourcing components to delivering finished, tested assemblies.

Applications for PCBs

PCB Assembly (PCBA) Process

Trust us to deliver precision, speed, and quality at every stage of your PCB project.

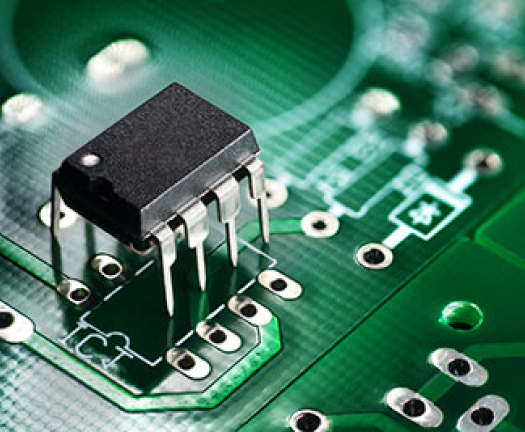

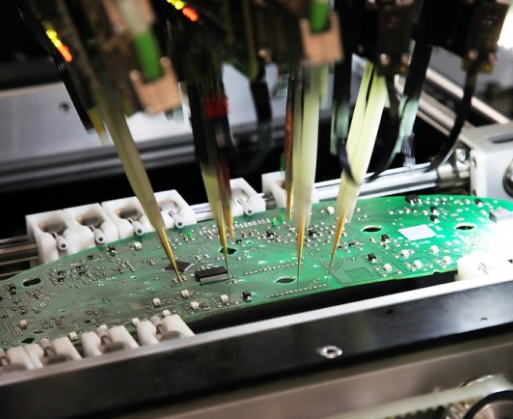

Surface Mount Technology

Surface Mount Technology (SMT) refers to mounting electronic components to the surfaces of printed circuit boards (PCBs). It’s a popular alternative to conventional assemblies whereby components are inserted through holes.

The real advantage of SMT and high-quality circuit printing is that it reduces manufacturing costs while also making better use of PCB space.

Due to the high level of automation inherent in SMT, it’s easy to build extremely complex electronic circuits into even the smallest of electronics assembly with reliable repeatability.

Furthermore, the popularity of this approach means there is also a wide range of surface-mount devices (SMDs) available.

At Hallmark Nameplate, we can combine our SMT services with any SMDs necessary to complete the PCB manufacturing & assembly your company needs. For our SMT assemblies, we rely on the following high-precision Samsung machines:

SM482

SM421

CP-40 Inline

CP-40 Stand Alone

Through-Hole Technology

As PCB manufacturing & assembly services become increasingly complex, often with surface mount components on either side, automating the soldering process of through-hole components can be a near-insurmountable obstacle.

Through-hole technology is the perfect solution for circuit printing and assembly. By soldering components through holes in a printed circuit board, the result is a stronger bond that can withstand greater degrees of environmental stress, including high temperatures and even collisions.

Through-hole components have either axial or radial leads. Axial lead components feature one or more leads extending from each end. With a radial component, all the leads come out of the same side.

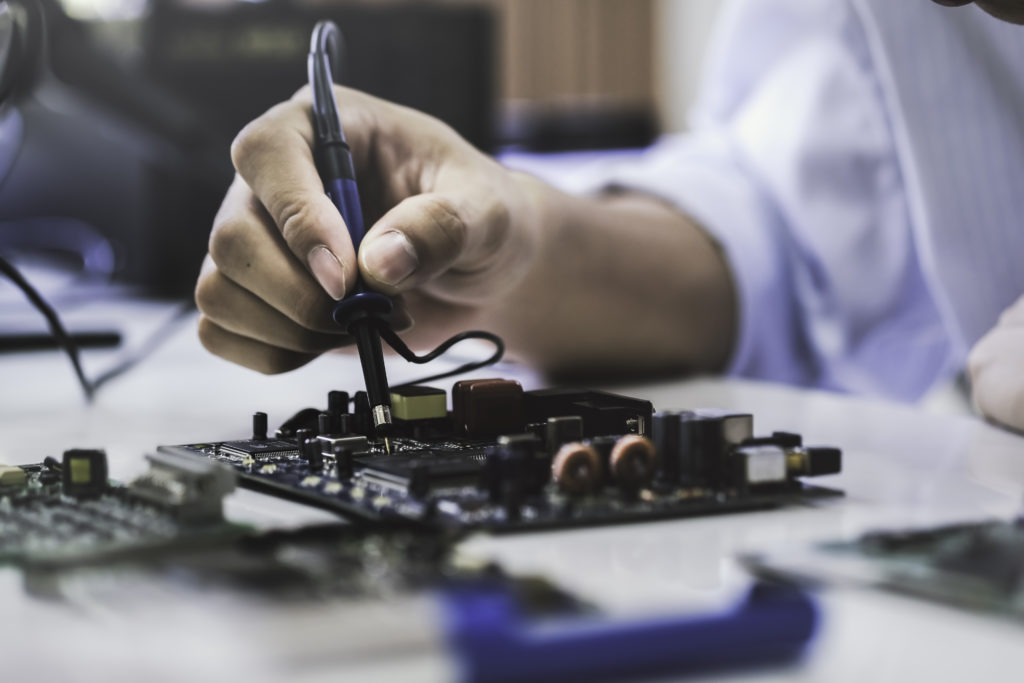

Soldering Process for Printed Circuit Board Assembly

At Hallmark Nameplate, we utilize two soldering techniques when creating custom printed circuit board assembly for our clients: wave and selective soldering.

Wave Soldering

Traditionally, the most popular solution for electronic assembly manufacturing has been to utilize wave soldering. This is accomplished by soldering the boards with a molten wave that the PCB can pass through. Wave soldering is ideal for projects that only require conventional through-hole components or those with particularly large surface mount components.

Selective Soldering

The other solution we can use is selective soldering. This is when a small bubble of solder is utilized to solder components together.

This method is becoming more and more common as the industry moves away from the assembly of larger PCBs of the past. Selective soldering is perfect for soldering smaller components on boards that are densely populated. As each section of the board is soldered individually, the soldering is far easier to control. Among other things, this makes it possible to adjust various parameters like thermal profiles and component heights

For both types of soldering, we use an Era Selective Soldering SMARTFLOW 2020.

Automated Optical Inspection

Automated optical inspections (AOIs) are absolutely essential for the quality control of PCB assembly and fabrication.

It goes without saying that Printed Circuit Boards must be tested before they are put to work, but proper inspections would be impossible without AOIs, which are fast, thorough, and cost-effective.

Among other things, our AOIs can discover surface defects like:

Excessive Solders

Incorrect Component Polarity

Incorrect Components

Insufficient Solders

Missing Components

Nodules

Opens

Scratches

Shorts

Stains

At Hallmark Nameplate, we conduct our AOIs early in the production process, so any potential issues are caught long before they can become much larger problems.

Of course, we can also modify our AOIs to meet any specific requirements you may have.

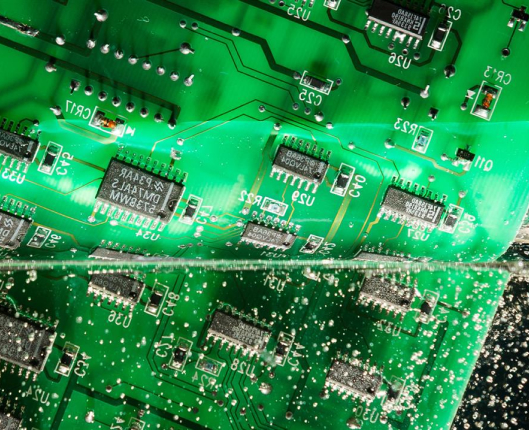

Conformal Coating

Conformal coating is essential for safeguarding the surfaces of your printed circuit boards (PCB). It will add to your board’s reliability while also securing its longevity.

As the name suggests, these coatings “conform” to the printed circuit board, so they don’t significantly add to its thickness or weight. You get the protection you want without sacrificing any of your printed circuit board assembly’s efficiencies or violating any restrictions regarding its dimensions.

This makes conformal coating the perfect solution for circuit boards installed in mobile devices, though they’re fantastic for any application.

These coatings are also completely invisible, so they can be applied to a circuit printing without blocking indicator lights or making text unreadable.

Conformal coating is often implemented to prevent PCBs from succumbing to harsh environments that may introduce:

Acids

Bases

Corrosion

Salt

Various Solvents

However, they’re also a reliable defense against the damage that can be done from constant vibrations coming from the machinery.

Prototyping

Designing the specific printed circuit board for your requirements is the first step to electronic assembly manufacturing. Next up is prototyping.

Our PCB manufacturing and assembly (PCBA) services will produce the samples you need for sufficient testing before proceeding with a much larger order. You’ll enjoy peace of mind knowing that you're working with an expert prototype USA PCB manufacturer that meets every requirement.

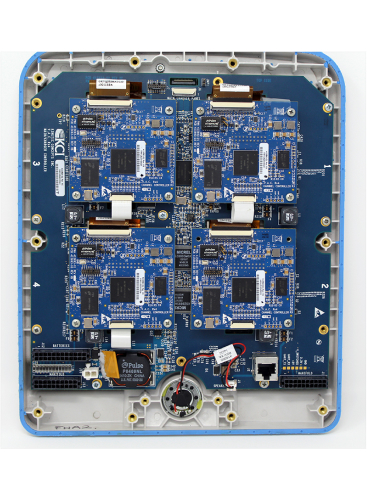

Box Builds and Turnkey Assembly

Box builds include all of the printed circuit board assembly work required for electromechanical construction, aside from the actual circuit board.

Our team takes a unique approach to each box build. We begin by first understanding exactly what you need from your box and answering any questions you may have. Only then do we begin the planning process.

In this way, you can outsource all of the manufacturing to Hallmark Nameplate. Our turnkey assembly ensures you get exactly what you want. There’s no need to settle for current boxes on the market or handle construction on your own.

With that being said, most of our box build PCB manufacturing services include the following steps:

Installing subassemblies

Installing other components

Routing cables or other wire harnesses

Fabricating the enclosures

We have the experience and equipment to add to those steps as necessary to create the perfect box build for your company.

Testing

By far, one of the most important PCB manufacturing services we offer is thoroughly testing the reliability of every electronic assembly we carry out. While we’re proud of our time-tested methods and years of experience, we still go the extra mile to ensure all of our assemblies are fully functional and work as designed.

We start with an automated optical inspection (AOI) using YesTech FX Series and YesTech FX-940.

Next, we take x-rays with a Nordson Dage Jade FP.

Only then do we proceed with our three main tests:

Temperature Humidity Testing

Thermal Shock Testing

Vibration Testing

In total, we have seven testing stations that are equipped with:

Pace Production Soldering Station

Hot Air Gun Soldering Rework/Repair System

Stereo Zoom Microscope w/ 6.7x-45x magnification

For in-circuit testing, our team uses an SPEA 3030 bed-of-nails tester.

FAQs

Ask Our Experts About Equipment Solutions

Our experts are always ready to help. Get in touch with us and we'll find the right solution to meet your needs.