For most devices, membrane switch components are meticulously designed with the user in mind. Every time you check out at the grocery store or click a button on your TV’s remote control, you interact with membrane switches. Even when I’m typing out these words, I am opening and closing the electrical circuit in my keyboard via membrane switches.

So, what exactly is a membrane switch? Well, that’s what we’re here to explore. In this blog, we will go over the key membrane switch components, what they are, and how they contribute to the functionality and reliability of these essential interfaces.

Let’s dive right in!

The 8 Key Membrane Switch Components

From the top layer that you touch to the circuitry that carries your commands, each component plays a critical role. Whether you’re a product designer, an engineer, or simply curious about the technology behind everyday devices, understanding these components will provide valuable insights. So, let’s get into it.

1.) Graphic Overlay

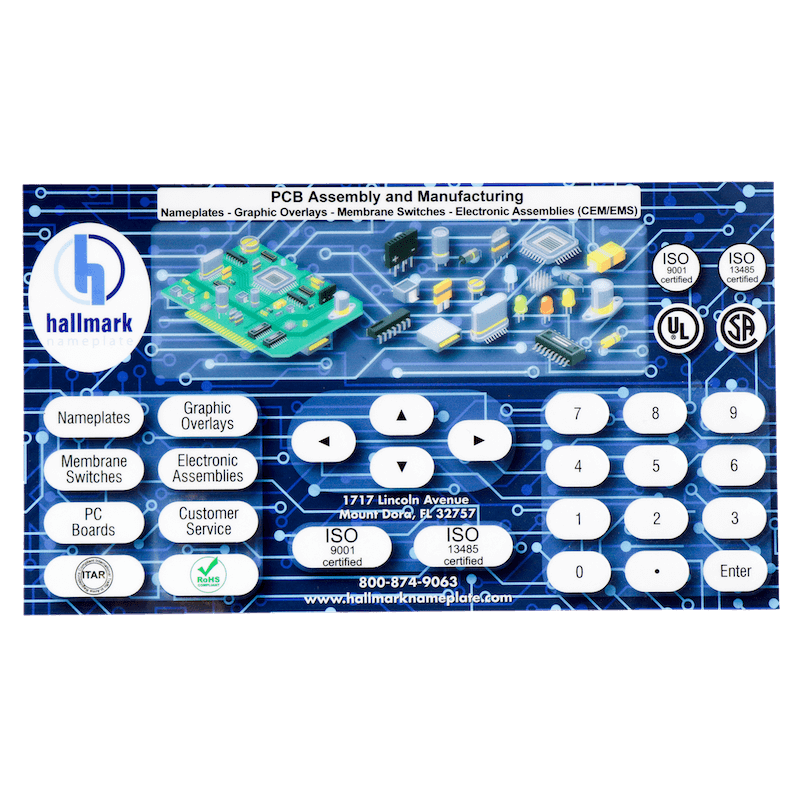

Now, this is the component you are most likely familiar with. The graphic overlay, also known as the faceplate or fascia, is the topmost layer of a membrane switch and serves as the interface between the user and the device. Typically, the overlay is screen-printed on durable polyester or polycarbonate materials.

The graphic overlay must withstand repeated use while providing clear and intuitive labels for the underlying buttons. It is customizable in color, texture, and design. Not only does this enhance the aesthetic appeal of the device, but it also ensures that the interface is user-friendly and easy to navigate.

2.) Mounting Adhesive

Next, the mounting adhesive layer secures the switch to the device’s control panel. This adhesive must provide a strong and durable bond, capable of withstanding environmental factors such as temperature variations, humidity, and mechanical stress.

Usually, the adhesive contains acrylic compounds that help ensure the membrane switch stays firmly in place throughout its time in operation.

3.) Tactile Layer

Membrane switch domes, also known as tactile domes, are critical for providing tactile feedback to the user. These domes are positioned beneath the graphic overlay and deform when pressed, creating a noticeable “click” that confirms the activation of the switch.

Usually, these are made from stainless steel or polyester. The domes come in a variety of sizes and materials, but metal is the popular choice. Overall, switch domes help enhance the user experience by providing a responsive and satisfying touch, which is crucial in applications where precise input is essential.

4.) Circuit Layer

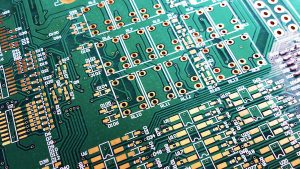

The circuit layer forms the core of the membrane switch, consisting of conductive pathways that connect the switch contacts to the device’s electronics. Typically, this layer is made from flexible printed circuits (FPC) or printed circuit boards (PCB), which can be customized to meet specific electrical requirements.

Moreover, the circuit layer ensures that signals are accurately transmitted from the switch to the device. Therefore, a reliable circuit layer is crucial to ensure the membrane switch operates efficiently. There are three main options for circuitry material.

- Silver: The most common choice is using silver conductive ink printed on polyester. It’s cost-effective and effective for standard membrane switches.

- Copper: Ideal for complex circuitry, copper flex circuits allow for soldering numerous components, meeting diverse design needs.

- Rigid Printed Circuit Board: Suitable for complex designs, this option supports more termination options. It typically involves printing silver ink on polyester, adding a contact surface of etched plated copper, and enclosing it in a PCB with epoxy insulation and a dielectric layer for protection.

5.) Circuit Tail

Next, the circuit tail is an extension of the circuit layer that connects the membrane switch to the device’s main circuitry. This flexible tail typically terminates in a connector that plugs into the control board for easy installation and replacement.

The design and length of the circuit tail are critical for ensuring a secure and stable connection, as well as for accommodating the physical layout of the device.

6.) Back Panel

While the back paned is optional, it provides structural support to the membrane switch assembly, ensuring that all layers remain aligned and securely bonded. This layer can be made from rigid or flexible materials, depending on the application requirements.

Moreover, this component can be especially useful in demanding environments where the device may be subjected to mechanical stress and vibration.

7.) Display Windows

Display windows are clear or tinted sections of the graphic overlay that allow users to view underlying displays or indicators. These windows must be optically clear and scratch-resistant to ensure long-term visibility and performance. Properly designed display windows provide important visual feedback to the user, such as status indicators or numeric displays.

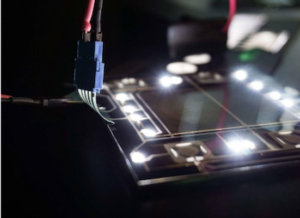

8.) Backlighting & Indicators

Finally, backlighting and indicators are essential for improving the visibility and usability of membrane switches in low-light conditions. These elements are integrated using various technologies, such as light-emitting diodes (LEDs), electroluminescent (EL) panels, or fiber optics.

Effective backlighting not only enhances the aesthetic appeal of the device, but also ensures that the interface remains functional and easy to use in any lighting environment.

What Are Membrane Switches Used For?

Now that you know the key membrane switch components, you will understand the impact of every button you press. The reality is that membrane switches are all around us.

Their durability, reliability, and ease of customization make them ideal for a range of products and environments. Here are some common uses for membrane switches:

- Consumer Products – Many household devices such as remote controls, microwave ovens, washing machines, and gaming consoles incorporate membrane switches. Their slim profile and responsive touch make them perfect for everyday consumer products.

- Medical Devices – The medical field utilizes membrane switches in equipment like diagnostic machines, hospital bed controls, and wearable health devices. Their sealed design helps maintain hygiene standards and ensures reliable performance in critical applications.

- Industrial Controls – Membrane switches are essential in industrial settings for machinery controls, control panels, and equipment interfaces. Their resistance to harsh conditions make them suitable for use in factories and other demanding environments.

- Aerospace & Military – Due to their reliability and ability to withstand extreme conditions, membrane switches are used in aircraft controls, military communication devices, and navigation systems.

- Automotive Applications – In vehicles, membrane switches are used for dashboard controls, infotainment systems, and keyless entry systems. Their ability to integrate seamlessly into complex designs while providing intuitive control makes them a popular choice in the automotive industry.

- Fitness Equipment – Treadmills, exercise bikes, and other fitness machines use membrane switches for their control panels. Their resistance to moisture and frequent use makes them ideal for this application.

As you can see, there are many applications for these devices. By providing a reliable and user-friendly interface in countless devices, membrane switches prove to be integral to modern technology.

Trust a Certified Electronic Assembler for Your Membrane Switch Needs

When you need electronic assembly, it’s important to find a trusted partner that upholds quality, reliability, and durability in all of their products. A certified electronic assembler brings a level of expertise and precision that is essential for creating high-performance membrane switches.

At Hallmark Nameplate, we pride ourselves on being a certified electronic assembler with decades of experience in the industry. We leverage cutting-edge technology and adhere to the highest standards to deliver membrane switches that meet and exceed your expectations.

Our commitment to quality, precision, and customer satisfaction sets us apart as a trusted partner for all your membrane switch needs. Trust Hallmark Nameplate to provide you with durable, reliable, and high-performance membrane switches.

Visit our website to learn more and request a FREE quote!