Here’s something we can all agree on: When designing and constructing buildings, there are always risks involved, especially when it comes to the use of complex equipment. So, how do you mitigate the risk of use? This is where architectural labels, overlay, or nameplate comes into play.

In this article, discover how the building industry can benefit from overlays, labels, and nameplates and learn how you can apply them in the field.

First, let’s talk about the common uses of architectural and construction overlays, labels, and nameplates today.

Key Uses of Nameplates and Labels in the Construction Industry

Whether you are sitting behind a drafting table or working in the construction field, you are likely using complex tools and equipment. Because of this, the building industry requires overlays, nameplates, and tags such as:

- Inventory and asset tags for design and drafting equipment

- Instructional nameplates for equipment

- Warning nameplates for dangerous areas

- Custom graphic overlays for mechanical and electronic assemblies

- Branding tags for drafting plan cases

Next, applications commonly include engineering design plans for buildings, office spaces, landscapes, residential homes, and institutional spaces.

Now, you may be wondering what the benefits are of using an architectural label or nameplate. Keep reading to find out.

Major Benefits of Architectural Labels

With any industry, there are benefits that come with using custom nameplates, overlays, and labels. When it comes to the architecture and construction industries, in particular, a label or nameplate specifically designed for each product, tool, or piece of equipment can have huge benefits for both the user and the business as a whole.

These benefits include:

- Increased organization – track and manage your construction equipment with specialized barcodes so you do not have to fuss with downtime.

- Improved sales – with an architectural label on your side, you can heighten your perceived value and brand awareness, which often leads to more sales.

- Better communication – users will gain access to better information on proper usage of equipment and products. With the manufacturer’s contact information included, users can seek help when necessary.

- Safer environment – Proper safety and warning labels keep your employees, customers, and your business safe and minimize risk.

Now that you understand the general benefits of using overlays, labels, and nameplates in the architecture and construction industries, let’s go into more specific uses.

Graphic Overlays in Architecture & Construction

When working in architecture and construction, you will come in contact with a lot of intricate equipment that requires special care and use.

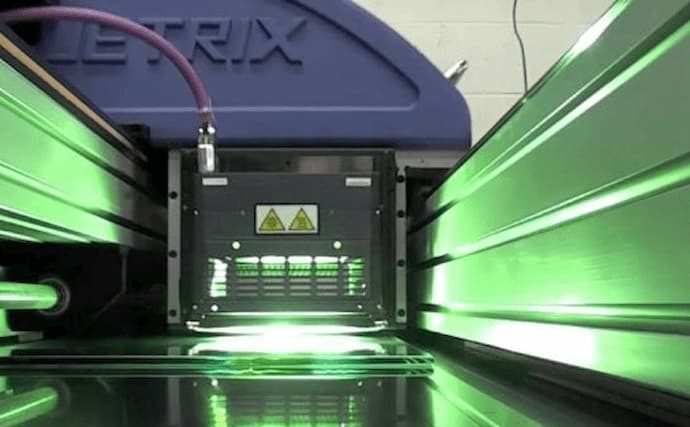

As heavy machinery can pose a potential workplace risk and increased liability for organizations, interfaces must be robust and easy to read, as well as intuitive. That is where graphic overlays come into play.

How Can a Graphic Overlay Benefit the Construction Industry?

A graphic overlay, also known as a panel overlay, a critical printed interface on mechanical and electronic assemblies allows the user to effectively interact with the device, machine, or equipment.

This top layer visually represents the device’s user interface panel, and it is the first thing the operator sees. There are various forms, such as a single layer that is backed by adhesive or part of a membrane switch.

These overlays typically include the company name and branding, in addition to product information like IDs and serial numbers, plus instructions for using the device. A graphic overlay may also include important safety warnings. This functional user-friendly interface is very important, as it helps define the user experience.

Common Uses of Architectural Overlays

Typical uses of graphic overlays include:

- Instructions – when using expensive, heavy-duty machinery there is no such thing as a small mistake. Eliminate risk by including instructions that explain to the user how to properly operate the equipment.

- Safety – working in the field, safety is a major concern. When your controls aren’t clearly visible to the user, for instance, emergency stop buttons, it can put them at risk.

- Durability – adding an overlay to your construction equipment can help to increase their lifespan. This is extremely helpful in the field where your equipment has to hold up against harsh conditions.

- Product Warning – overlays and their design help increase the visibility of equipment and facility warnings.

- Brand Recognition – using custom branded overlays on your products and equipment can help the end-user better identify your business. This can be done by including your business’s name, your branding colors, or your logo.

Now that you know all about graphic overlays, let’s talk about the key purpose of an architectural label.

Labels in Architecture & Construction

Machinery and heavy-duty equipment require labels that can withstand harsh conditions and meet industry specifications. The architecture and construction industry often use labels for asset tracking and safety, using them in the field and on equipment.

The 3 main labels and tags are:

- Inventory and asset tags

- Warning labels

- Branding tags

These tags are added to drafting tables, tools, cases, machinery, and throughout the construction field.

So, what are their purposes?

Key Purposes of Architectural Labels?

Businesses in the architecture and construction industries use labels to facilitate their building design and construction. Labels share vital instructions and safety warnings as well as provide quality control.

Typically, labels are placed on architectural tools and construction equipment in order to provide the necessary information. They usually contain barcodes, ownership details, manufacturer’s name, serial number, and maintenance requirements.

Once you have decided the purpose of your label, you can begin to select the material you want to use.

Common Materials for Architectural Labels

To start, there are 2 main types of materials you can select for your labels. These include:

Polyester (Mylar®) – Polyester, also known as Mylar, is ideal for harsh indoor and outdoor environments, since it’s UV resistant, won’t fade in the sun, is non-yellowing, electrical resistant, and can withstand extreme temperatures, water, abrasion, and chemicals.

Polycarbonate (Lexan®) – Lexan is a polycarbonate resin thermoplastic material that’s transparent, strong, tough, impact-resistant, and temperature resistant. It’s the best material to use where extreme temperatures and widely varying temperatures are a concern. This material is also resistant to scratches, corrosion, chemical abrasion, and water, and it expands and contracts without damaging the material.

Nameplates in Architecture & Construction

Nameplates are critical to the safety and efficiency of anyone who works in these intricate industries. One of the main types of plates used in architecture and construction are builder’s plates.

These typically can be found on:

- Bogies

- Construction equipment

- Rolling stock

- Automobiles and other transportation

- Household appliances

- Bridges

Nameplates provide critical information.

Common information included on nameplates are:

- Manufacturer’s name

- Location of manufacturer

- Model number

- Serial number

- Date of manufacture

Now that you have a better understanding of how you can use nameplates in the architecture and construction industries, we will discuss choosing the right materials.

Common Materials for Architectural Nameplates

Along with Polyester (Mylar®) and Polycarbonate (Lexan®), other durable materials you can choose for your nameplates include:

Stainless steel – it is durable in high temperatures and harsh chemicals. Stainless steel is also more sanitary than other materials because bacteria does not adhere to the metal and it is easier to clean.

Aluminum – this is an ideal material for architectural and construction nameplates because it is durable, lightweight, scratch-resistant, and cost-effective. It can stand up to harsh weather as well as various chemicals.

Vinyl (PVC) – PVC vinyl, also known as polyvinyl chloride, is very rigid and extremely durable. However, unless it has UV overlaminate protection, it isn’t suitable for outdoor use. Properties of PVC include resistance to moisture and humidity as well as low cost.

How to Choose the Right Manufacturing Process for Nameplates

Once you’ve selected the material you are going to use, it’s time to decide which manufacturing process you want to go with.

The most common process for architectural nameplates include:

Embossing – this creates raised numbers and letters in metal and is very durable with enhanced legibility.

Screen Printing – using colored ink your design is printed on the top layer of your metal surface. This process is recommended for projects that do not have to withstand harsh conditions, like warning signs.

Doming – custom domed nameplates have a 3D effect that stands out to create a strong brand design. This process is not recommended for outdoor use because extended sunlight exposure can cause damage to the underlying print.

Photo Anodization – During this process, your design is placed under a layer of aluminum to withstand extreme temperatures.

Choosing the right material and process can be tricky. Avoid the headaches by working with a manufacturing facility that has years of experience in the architectural and construction industry.

Create The Perfect Architectural Label, Overlay, or Nameplate with Hallmark Nameplate

At Hallmark Nameplate, we offer a full range of materials, thicknesses, finishes, adhesives, and special processes to meet the demands of the architecture and construction industries.

With extensive engineering and manufacturing expertise, we work with you to create the best nameplates, overlays, and labels for your application.

Ready to create the perfect architectural label for your business? Get a FREE quote to get started.