Hallmark Nameplate is excited to announce the addition of two additional flatbed digital printers to our lineup. Staying up to date with the most modern methods and technologies is what keeps our business at the top of the game. Creating products with advanced equipment is our specialty and bringing in two of the most sophisticated digital printers available at the moment will allow us to continue to do what we do best, and make products that live up to our name.

As always, Hallmark Nameplate is committed to quality. The flatbed digital printer has proven itself through numerous displays, awards, and tests that it is the most highly developed machinery of its kind right now. Adding these two new pieces of equipment will keep Hallmark Nameplate right where we want to be as far as quality and customer service. Our products will only continue to improve and reach new heights as we maintain our status as a leading manufacturer of printed materials.

“The… UV printer is an extremely high-quality UV printer built from the ground up for high volume production of control panels, promotional items, awards, trophies, packaging prototypes, POP displays and signs 4×4-feet or smaller,” said Jeff Olson, National Sales Manager for Seiko Instruments USA. “We believe [the printer] fills a need in the industry between large 4×8 flatbed UV printers and smaller, slower UV printers that many shops are currently using.

These new flatbed digital printers can reach print speeds of up to 284 sq ft/hr and offers a resolution of 1440 dpi; the CMYK + White printer features six Konica 1024 printheads, 6-picoliter drop sizes, and three-layer white capability. The capabilities of the flatbed digital printers allow the range of their services to be extremely wide. Whether they are used for indoor, outdoor, or industrial applications, these printers are both tough and detailed enough to be aesthetically pleasing as well as durable for any product manufactured at Hallmark Nameplate.

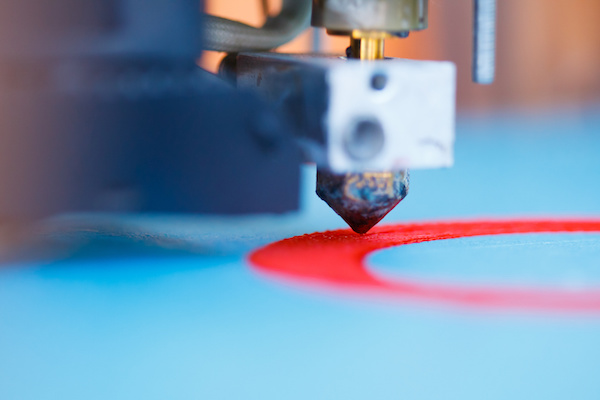

UV printing is a form of digital printing that uses ultra-violet lights to dry or cure ink as it is printed. This benefits our customers in a huge way because it takes the production capabilities at Hallmark Nameplate to new heights. The flatbed digital printers that we are bringing in will allow us to print directly onto any material with record speed and incredible detail. As always, Hallmark Nameplate upholds the importance and value of maintaining the highest industry standards for environmentally responsible printing processes and these printer additions allow us to continue to do so.

Not only do these printers give Hallmark Nameplate the ability to produce better products at a higher speed, they allow us to do that while being as environmentally conscious as possible. The UV printing process is more environmentally friendly than the alternatives because it produces fewer VOC’s, odors, and heat while running. It is also a safer option for the operators of the machines. The flatbed digital printer does not expose the UV lamp light as much as it’s competitors, which is a benefit that Hallmark Nameplate recognized for the eye safety and health of employees.

The benefits of the digital printers go beyond being able to create more detailed products using a faster and safer machine. The actual product will improve as well. The strong adhesive that is the result of the UV light creates a finish that is guaranteed not to chip when routed or cut. It can also fold without cracking when applied to softer substrates. The detail that the Jetrix flatbed digital printer provides along with the durability is extremely rare, and is paving the way for printing.

These new additions to our lineup of equipment at Hallmark Nameplate will only add to our commitment to quality, individualized customer services, and product expertise. We pride ourselves in offering our customers the best and most efficient products, and staying up to date with techniques and machinery is just one of the ways we work to do so. Call Hallmark Nameplate today for a fast, free quote, or to learn more about our recent addition of the two flatbed digital Printers.