Wave Soldering vs Selective Soldering: Perfecting Your Electronic Assembly Process

Should you use the wave soldering process or selective soldering process in electronic assemblies? The answer depends on the intended use of your PCB.

As electronic devices get more complex, so do their electronic assemblies. So, what are the different ways to create a strong electronic assembly and how can you keep up with the more advanced components and their requirements? The answer lies with soldering.

Simply put, soldering is a term that describes a process that uses a metal alloy to create a strong permanent bond between elements in electronic assemblies, such as a circuit board.

In this article, we’ll dive deeper into the world of electronic assemblies and soldering, and learn:

- What is an electronic assembly

- Proper ways to create circuit boards

- Key differences between the wave soldering process vs the selective soldering process

Let’s start by defining the purpose of electronic assemblies and some of their uses.

What is an Electronic Assembly?

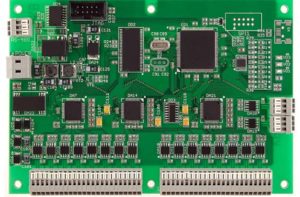

Custom electronic assemblies, also known as printed circuit board assemblies, involve mounting components to the wiring of a printed circuit board (PCB).

The PCB is the foundation of electronic devices. A PCB has pathways that connect electronic components to transfer electricity. Additionally, it provides support for your components.

There are two main ways to create circuit board assemblies:

- Surface Mount Technology

- Through-Hole Technology

Depending on the type of PCB assembly different soldering processes will be used.

Soldering Processes for a PCB Assembly

There are two main soldering techniques when creating custom printed circuit board assembly:

- Wave soldering

- Selective soldering

You may be wondering what these two processes are and how they differ. Keep reading to learn the pros and cons of each.

Key Differences Between Wave Soldering & Selective Soldering

When choosing which process to use for your electronic assembly it is important to understand their differences. Each soldering process has its advantages and disadvantages that can affect the end product.

Let’s begin with what wave soldering is.

What is Wave Soldering?

Traditionally, the most popular solution for electronic assembly manufacturing has been to utilize wave soldering. This process, also known as flow soldering, has been the standard process for many years.

Flow soldering is ideal for projects that only require conventional through-hole components or those with particularly large surface mount components.

The Process

First, you spray a layer of the flux in order to clean the components of impurities.

Then you preheat the board to activate the flux. This also protects the board from thermal shock.

The PCB then passes through a molten wave making an electrical connection between the components and PCB. If you are soldering a double-sided PCB you will need to pass it through twice.

This process is performed in a protective nitrogen area in order to reduce any defects.

Pros of Wave Soldering

Wave soldering is perfect for simple soldering where you have a high quantity to do in a short amount of time.

The advantages to using flow soldering include:

- Easy setup

- Improved speed

- Cheaper process

While there are advantages to using the flow soldering process, it also has its disadvantages

Cons of Wave Soldering

While the setup is easy, post-cleanup takes longer because of the molten wave. It also may require additional reworking which, in the long run, can make the process more work.

Additionally, flow soldering requires more material, such as solder, flux, electricity, and nitrogen, to complete the process. Keeping up with the high rate of consumption can become expensive.

Next, let’s explain what selective soldering is.

What is Selective Soldering?

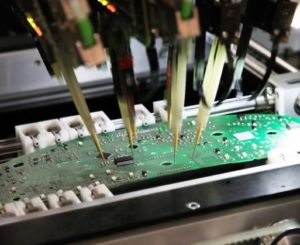

The other process is selective soldering. Selective soldering is a process where you solder individual through-hole components on a PCB using a solder fountain or head that moves to solder from underneath.

This method is becoming more and more common as the industry moves away from the assembly of larger PCBs of the past. Double-sided PCBs have become more common which use smaller components.

The Process

First, apply flux to the components that will be soldered. Then you preheat the board to activate the flux.

Then with an automated nozzle solder-specific components locally on an x-y gantry to the PCB.

Pros of Selective Soldering

Selective soldering is perfect for soldering small components on boards that are densely populated. As each section of the board is soldered individually, selective soldering is far easier to control.

Among other things, this makes it possible to adjust various parameters like thermal profiles, pitch, and component heights.

Other advantages of selective soldering include:

- Improves reliability of solder joints

- Removes the need for fluxing all components

- Less expensive

- Process optimization

Most importantly selective soldering provides consistency so you can easily reproduce the project.

Selective soldering is perfect for difficult conditions such as:

- Tall component height – tall components may block the wave from soldering

- Tight spacing – if a thru-hole component is close to an SMT component then there is not enough room for flow soldering

- Uneven heating – certain thick metals cannot be heated thoroughly enough to form a solid solder joint with the flow soldering

- Dence concentration – large connectors close together can make it difficult to reach the pins with wave soldering

As you can see there are a lot of advantages to using selective soldering which is why so many people are beginning to use it more. That being said there are still disadvantages to using selective soldering.

Cons of Selective Soldering

Like flow soldering, selective soldering also has some disadvantages.

For starters, the setup is more complex because it uses unique programming for every board

The soldering process is also more time-consuming than its counterpart and, therefore, is not efficient for producing high quantities.

Nevertheless, selective soldering is great for those who value precision and high-quality end results.

Create a Durable Electronic Assembly with Hallmark Nameplate

Whether you want to assemble your electronics through wave or selective soldering, Hallmark Nameplate ensures your soldering needs are professionally met.

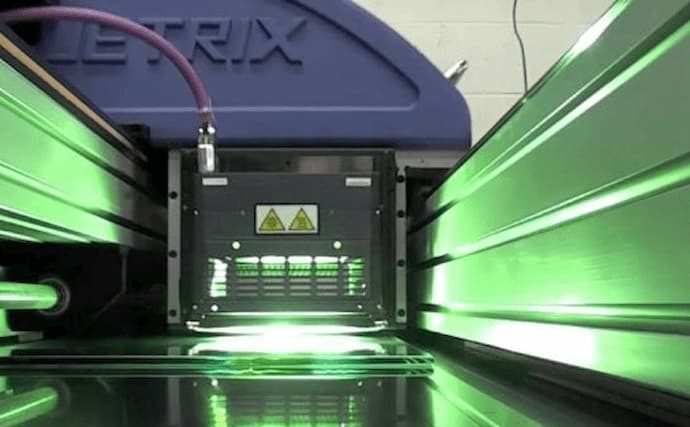

At Hallmark Nameplate, we provide prototyping during our PCB assembly so you have peace of mind knowing that your electronic assembly exceeds expectations. Furthermore, for precise and efficient soldering, we use an Ersa Selective Soldering SMARTFLOW 2020. Not only that, but we also run several thorough tests including temperature humidity, thermal shock, and vibration testing.

Ready to start your electronic assembly? Our experts are always ready to help. Get in touch with us and we’ll find the right solution to meet your needs.