How the Aviation Industry Can Benefit From Nameplates and Labels

When you think of aviation, images of large jet engines, a set of wings, and airplane propellers probably pop into your mind. When operating such magnificent machinery, aviation nameplates and labels are quintessential to the safety of anyone who works in this extraordinary industry!

In fact, plates, overlays, and labels are essential to risk management and help communicate vital information. In this article, discover how the aviation industry can benefit from nameplates and learn how you can apply them in the field.

First, let’s talk about the common uses of aviation nameplates and data plates today.

Common Uses of Nameplates in the Aviation Industry

Some of the most common aviation nameplates include metal, safety warning, instructional, and barcoded nameplates.

For starters, metal nameplates are commonly used for model and serial numbers while barcoded nameplates are applied to electronic components.

On the other hand, instructional nameplates give detailed descriptions about how to operate the product in a step-by-step manner while safety warning nameplates highlight how to handle the machinery correctly and safely, including caution and “do not touch” labels.

The aviation industry also utilizes many other kinds of plates, overlays, and labels. These include:

- Parts labels

- Troubleshooting schematics

- Brand tags

- UID tags

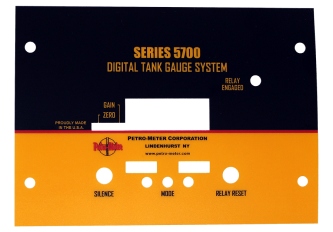

- Control panel overlays

- Customized dials

So, how exactly do these plates, overlays, and labels benefit the aviation industry?

Key Benefits of Aviation Data Plates, Overlays, and Labels

Here’s a fact: the aviation industry always needs to abide by the highest safety standards because there is such a huge risk of danger in the field. That is where nameplates, overlays, and labels come into play.

When you install an aviation data plate, such as an instructional or safety warning nameplate onto your aircraft and aviation equipment, you instantly help manage the risk of use and make your processes much more efficient.

Here are some key benefits of using plates, overlays, and labels on your aircraft, equipment, and other products:

- Foster a safe environment: Without the proper safety identification, you are putting your employees, customers, and your business at risk. Consequently, warning labels and safety signs help to minimize potential safety risks.

- Track your assets to stay organized and manage your equipment: If you lack traceability and asset management on your components, you may end up wasting time with corrections and experience downtime trying to track things down. Luckily, barcodes plates make it easy to track and manage your assets.

- Show proper uses and safety warnings on your equipment: The aviation industry uses a lot of important, complex equipment. Without knowing the proper uses and processes, there can be a lot of potential hazards.

Most importantly plates, overlays, and labels help you comply with major legal regulations. Keep reading to learn how.

Comply with Federal Aviation Administration (FAA) Regulations

With so many active state and federal regulations surrounding the aviation industry, the importance of labels, overlays, and plates has increased tenfold.

Because of this, it’s important to stay within compliance with these regulations if you want your business to run smoothly and to keep everyone involved safe. Here’s what you need to know if you want to federally comply with marking aviation products and equipment.

Include All Required Data in Aviation Nameplates

Your aircraft needs to have all of its data openly marked on a nameplate in order to make sure every important piece of information is clearly visible and easy to access.

Required data include:

- Manufacturer’s name

- Model

- Serial number

- Certificate number

- Ratings for engine

- Production certification number

Furthermore, the nameplate manufacturing facility you work with should be able to help you make sure all required information is on your plate and is durable.

Make Sure Identification Plates Are Fireproof

Next, your identification plates will most likely be marked on multiple components that produce a lot of heat. Therefore, you will want to make sure that your identification plates are fireproof.

In case of a crash, engine blow, or other equipment malfunction, you will need all of your important identification to withstand any fires, high heat, and flames.

Therefore, when selecting your aviation data plate, you need to be selective with the material and processes used.

Properly Secure Plates to Aircraft and Equipment

Finally, all plates must be able to stay secure and safely fastened during routine maintenance, flying, turbulence, and even crashes. Plates should not be placed on the interior of the aircraft because they need to be seen and easily accessible from the ground.

How to Select the Right Material For Your Aviation Nameplate

Furthermore, in order to be able to stand up against the extreme elements outdoors, your nameplates must be sturdy so no important information gets destroyed. To comply with these regulations, it is important you select the right material for your aircraft.

Stainless Steel

This material is durable and sturdy and can hold up to extreme conditions.

While this is a great option for someone looking for a long-lasting material, if you are working on a lightweight aircraft then you might want to consider a different material, like aluminum.

Aluminum

Aluminum is the best lightweight option compared to any other metal. Don’t worry, although it is lightweight, it is still very durable.

It also has the benefit of being able to use the Metalphoto nameplate process.

Metalphoto

Metalphoto, a photosensitive anodized aluminum, can handle extreme temperatures and stand up against corrosion and abrasion. This material is both durable and lightweight.

People go with this process to include imagery that stands the test of time sealed within a sapphire-hard anodic layer.

Find Nameplates Engineered for the Aviation Industry

If you want the best aviation data plates, labels, and overlays for your aircraft and other equipment, then Hallmark Nameplate is the place to go. For decades, our team has worked with the aviation industry and has expert experience in designing and manufacturing durable plates, overlays, and more.

Some of our offerings include:

- Identification products – These plates and tags identify and trace components as well as enhance communication.

- Overlays – Overlays are used for cabin controls, identification placards on commercial cabins, safety labels, cockpit controls, galley equipment, and ground equipment.

- Membrane switches – Our membrane switches are perfect for cabin and cockpit equipment, galley equipment, and ground equipment. We can also make your components night vision compliance.

- Capacitive switches – The benefit of capacitive switches is that they can be applied to curves and are very durable. These are often used for cabin controls and galley equipment.

- Specialty printing – Have something different in mind? We can help you print any special aviation components you need for your projects.

As you can see, we have many different offerings for the aviation industry and we’d love to help you with any of your projects. Ready to work on your custom aviation projects? Connect with us and request a quote.